-

View Products

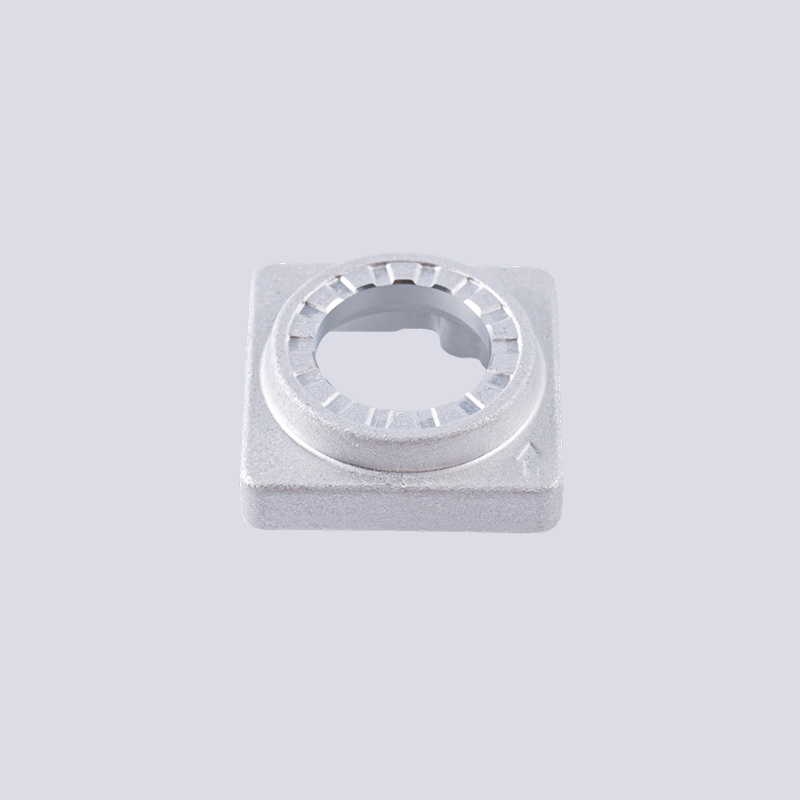

View ProductsYC013400167501 Series High-Precision Cold-Extruded Vehicle Camera Housing

Product Highlights

1. High Strength & Reliability

Utilizing cold extrusion technology, the housing's strength, hardness, and fatigue resistance are significantly enhanced through plastic deformation. This ensures excellent impact toughness and structural integrity in harsh vehicle environments, meeting the high durability requirements of smart driving systems.2. High Precision & Consistency

Combining Deforming simulation molding with 3D modeling design, the housing achieves single extrusion molding without draft angles, with dimensional accuracy up to ±0.03mm. Stable full-process technology ensures high consistency across mass production, perfectly meeting the demands of automated assembly lines and high-precision welding (such as coaxial welding).3. Lightweight & High Material Efficiency

Cold extrusion is a near-net-shape process, with material utilization exceeding 90%. It ensures a lightweight design while reducing waste, aligning with the lightweight development trends of new energy vehicles.4. Full In-House Production & Strict Quality Control

The entire process—from aluminum forming to surface treatment (ultrasonic cleaning, passivation, oxidation, salt spray testing)—is independently controlled in-house. This guarantees the housing meets automotive-grade standards for corrosion resistance, airtightness, and thermal conductivity. -

View Products

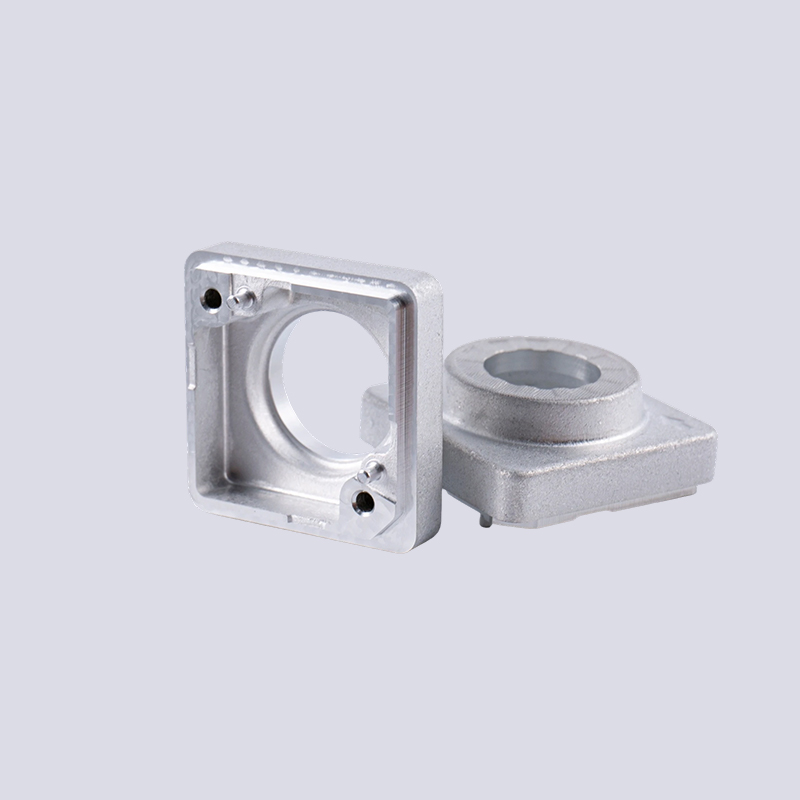

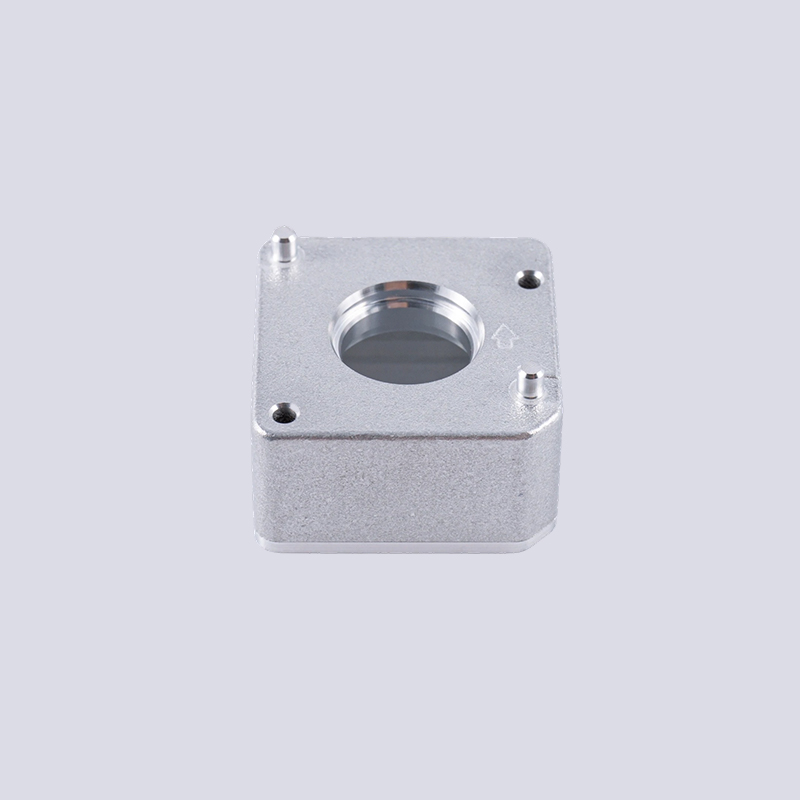

View ProductsHigh-Precision Aluminum Alloy Vehicle Camera Housing (Model: YC013600308800)

Product Overview

The YC013600308800 is an aluminum alloy vehicle camera housing manufactured using cold extrusion single-stroke forming technology, specifically designed for smart driving vision systems. With high-dimensional accuracy, lightweight construction, and excellent reliability as its core advantages, the product perfectly meets the automotive industry's stringent demands for precision components that are "lighter, stronger, more reliable, and lower in cost." -

View Products

View ProductsAs an innovative leader in the application of cold extrusion technology for precision automotive components, Longto Alloy Technology closely collaborates with Ruibo Sensing Technology (Hebei) Co., Ltd. to provide high-precision, highly reliable camera housing solutions for intelligent driving systems. Below are the product series and key technological advantages customized for our core partners:

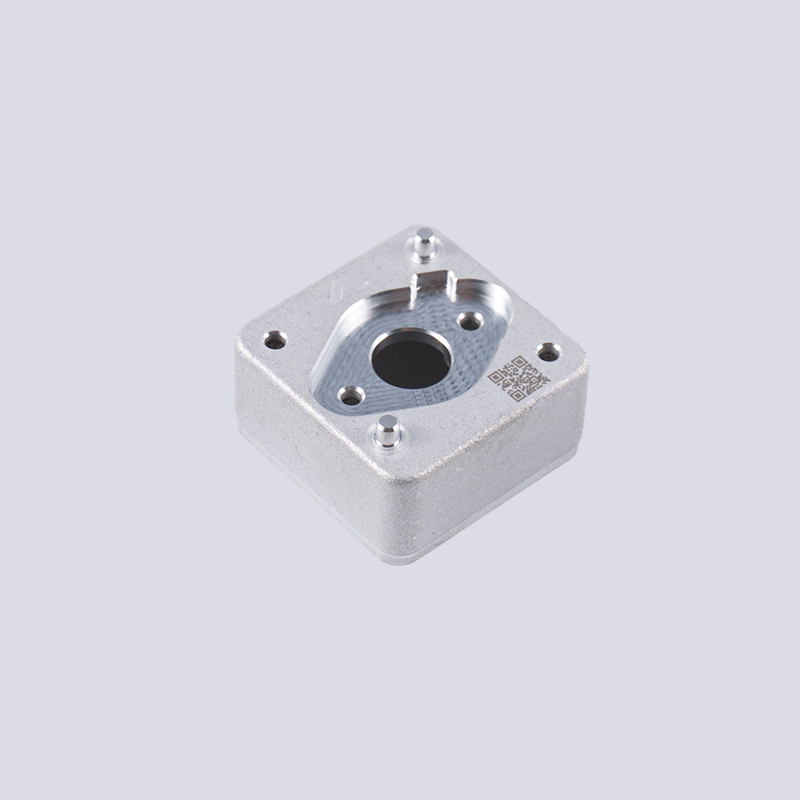

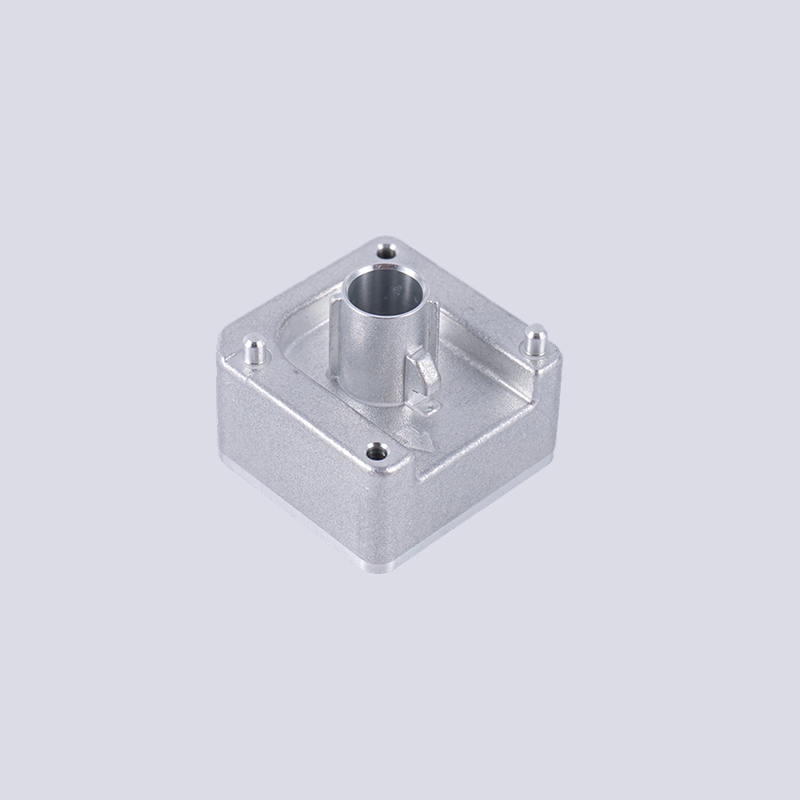

Product Series: GWM_DE09 Side View Camera Back Cover

Technology & Process: Utilizes advanced cold extrusion forming technology, combined with DEFORM simulation modeling and 3D design, to achieve single-step extrusion forming, ensuring a tightly structured housing with no draft angle.

Core Advantages:

High Precision & Consistency: Through precise CNC clamping and full-process control, millimeter-level dimensional tolerances are guaranteed to meet stringent automotive environmental requirements.

Lightweight & High Strength: Based on expertise from aerospace communication component R&D, aluminum alloy materials are used to achieve both weight reduction and structural strength enhancement.

Surface Treatment: Includes ultrasonic cleaning, surface passivation, oxidation treatment, and salt spray testing, ensuring corrosion resistance, interference immunity, and compatibility with complex automotive environments.

Production Capacity: Supported by a mature cold extrusion process, production capacity continues to scale up, targeting an annual output of 30 million sets within the next three years to rapidly respond to market demands. -

View Products

View ProductsAs an expert in high-precision formed component manufacturing, we leverage the 15-year foundation in cold extrusion technology from our parent company, Longto Alloy Technology, originally developed for aerospace communication applications. We have successfully adapted this advanced precision cold forming process to the field of smart driving core components. The 70-0128-001 Cold Heading product we provide to our industry partner, Suzhou Xianglong Jiaye Electronic Technology Co., Ltd., is a prime example of this technological translation.

-

View Products

View ProductsAs a manufacturer specializing in high-precision formed components, we leverage the technical foundation of over 15 years in cold extrusion connectors for aerospace communication from our parent company, Longto Alloy. By applying advanced metal plastic forming technology to the automotive smart driving sector, we have successfully developed a series of high-precision, high-reliability camera housing products.

-

View Products

View ProductsBased on your company's over 15 years of technical expertise in precision metal forming and successful collaboration with globally renowned automotive supply chains, we introduce our high-precision Cold Extrusion Camera Housing product series for the smart driving sector.

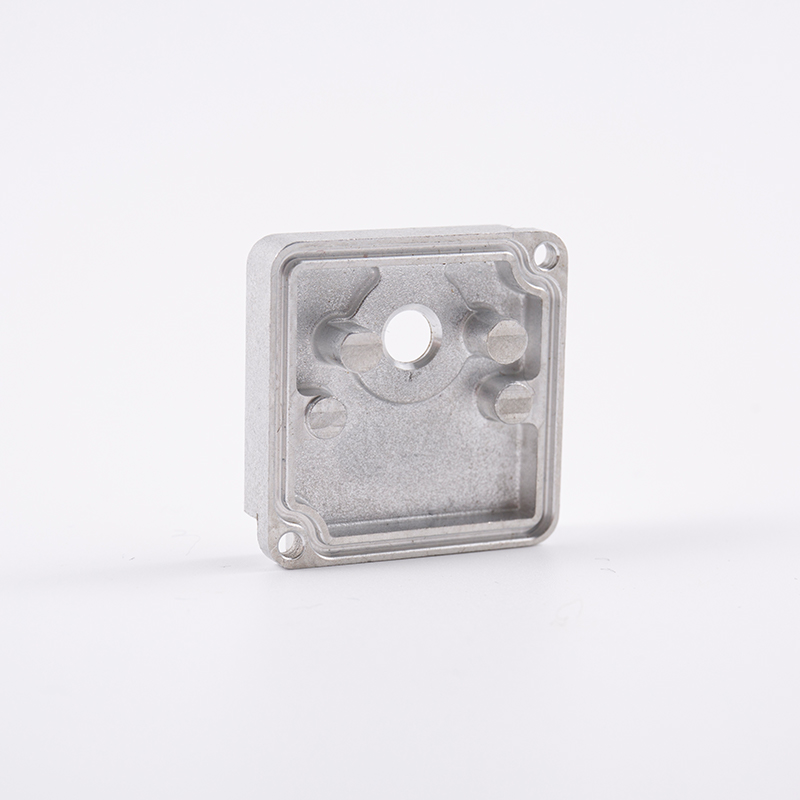

Core Product: 70-0131-001 Cold Heading Vehicle Camera Housing

This product is manufactured using advanced Cold Extrusion (also known as Cold Forging) technology, specifically designed for automotive vehicle cameras. We are committed to becoming the industry standard setter for cold extrusion camera housings, providing customers with cost-effective, highly reliable critical components through innovative processes. -

View Products

View ProductsWe specialize in providing high-precision, high-performance solutions for vehicle camera housings and sensor housings for intelligent driving. Leveraging the 15 years of profound technical heritage in cold extrusion for aerospace communication connectors accumulated by our parent company, Longto Alloy Technology, since 2009, as well as successful supply experience for global renowned clients such as Jaguar Land Rover, we are committed to redefining the performance standards of vehicle precision components through innovative metal plastic forming processes.

-

View Products

View ProductsAs a partner of TE Connectivity, we are committed to delivering exceptional aluminum alloy housing solutions that meet the stringent requirements for high-precision, high-reliability components in the smart driving sector. Below is an introduction to our representative product series, developed based on core technologies and processes:

Core Product: High-Performance Vehicle Camera Housing

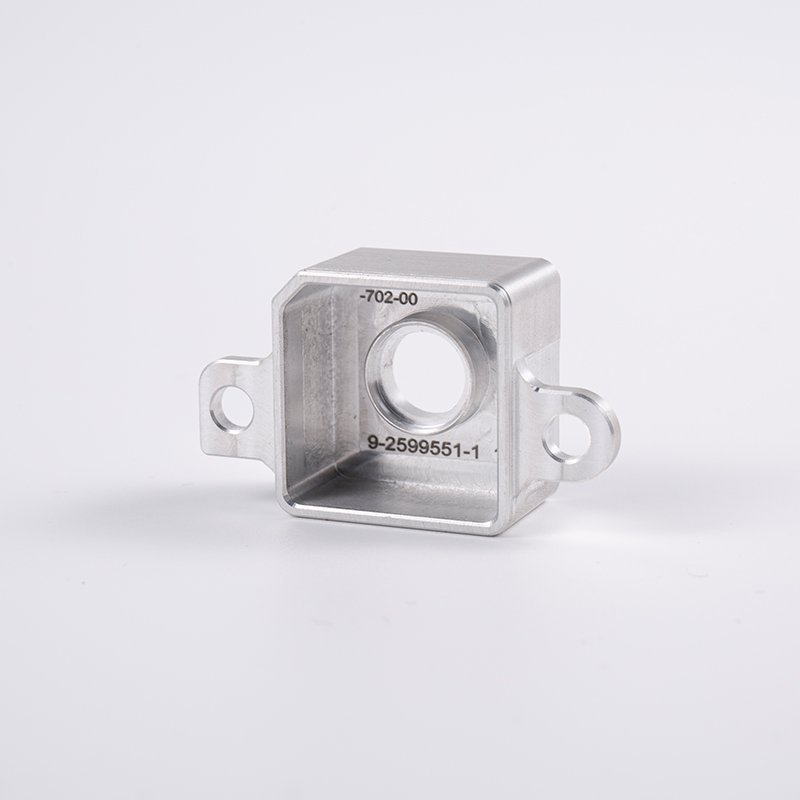

Example Product Model: 9-2599551-1_1_20250929

This product utilizes high-performance aluminum alloy materials (such as Al1070/AL1050) and is formed through advanced cold extrusion technology in a single process. It offers excellent heat dissipation and welding reliability, meeting diverse customer demands for material performance and environmental adaptability. -

View Products

View ProductsAs a partner of TE Connectivity, the 2419604-3 series vehicle camera housing we provide represents the exceptional application of metal plastic forming technology in the field of precision component manufacturing. This product is specifically designed for smart driving systems to meet the automotive industry's stringent requirements for reliability, precision, and durability.

-

View Products

View ProductsThe 2520138_A is a high-performance aluminum alloy housing designed specifically for advanced vehicle camera and sensor systems. Manufactured using the advanced one-shot cold extrusion process, this product perfectly integrates materials science, precision forming, and simulation technology. It is engineered to meet the stringent requirements of the smart driving sector for core components that are "lighter, stronger, more reliable, and more cost-effective."

-

View Products

View ProductsAs a partner to NIO, we supply high-end, customized automotive camera housings (Product Code: LOTUS.20241226) for its intelligent driving systems. Specifically designed for next-generation smart driving cameras, this product is manufactured using advanced Cold Extrusion (also known as Cold Forging) technology, representing the cutting-edge application of Metal Plastic Forming in the current field of automotive Sensor Housings. We are committed to being a reliable cornerstone in the manufacturing of Core Components for Intelligent Driving.

Aluminum Camera Shell Of Vehicle

Application: Advanced Driver Assistance System (ADAS) Blind Spot Detection Driver Monitoring System (DMS) Front View Camera Rear View Camera Surround View Camera

Material: Al1070, reliable purity brings excellent heat dissipation of the product, which can ensure the reliability and stability of laser welding on the client side.

CNC: reliability of machining clamping;

Development: product tolerance and fit; structural design;

PPM: stability and consistency of product quality;

Longto Precision Industry (Zhejiang) Co., Ltd.

-

Skilled Workers: 100+

Skilled Workers: 100+ -

Estimated Output Value: ¥300M+

Estimated Output Value: ¥300M+ -

Annual Capacity: 30 Million Units

Annual Capacity: 30 Million Units

News

How Aluminum Camera Shell Design Influences Vehicle Camera Performance and Installation Stability?

The design of an aluminum camera shell plays a critical role in ensuring that vehicle camera systems perform reliably under demanding automotive conditions. From structural rigidity to thermal management, the engineering behind the shell directly affects imaging clarity, long term durability, and installation accuracy.

Structural Strength Ensures Stable Camera Positioning

A well designed aluminum shell provides high stiffness and impact resistance. This prevents micro vibrations and deformation that could cause image blurring, misalignment of optical components, and calibration drift in ADAS systems. Aluminum rigidity helps the lens and sensor remain fixed in precise alignment even under road impacts, vibration, or harsh weather.

Improved Thermal Management Enhances Image Quality

Cameras generate heat during operation, and temperature fluctuations can impact image sensors. Aluminum has excellent thermal conductivity. When the shell is designed with optimized geometry such as heat dissipating fins, it helps reduce internal temperature, prevent sensor overheating, maintain consistent image performance, and extend camera lifespan.

Corrosion Resistance Improves Long Term Durability

With proper design and surface treatments such as anodizing, aluminum shells resist water exposure, road salt, chemicals, and oxidation. This prevents corrosion related mechanical failures or optical obstruction and ensures reliable operation over time.

Lightweight Construction Supports Better Vehicle Integration

A lightweight aluminum shell reduces strain on mounting brackets and electronic components. This improves installation flexibility and compatibility with compact ADAS and autonomous driving modules while helping meet vehicle packaging and weight targets.

Precision CNC Machining Improves Alignment Accuracy

Aluminum can be machined to tight tolerances, enabling shells that ensure precise alignment between lens and sensor, accurate mounting positions, and compatibility with automated assembly processes. This precision directly affects image clarity and long term calibration stability.

Protective Design Enhances Environmental Reliability

Aluminum shells can be engineered with features such as sealed housings to meet IP67 or IP69K ratings, shock absorbing internal mounts, and reinforced corners for crash resistance. These design choices protect delicate electronics inside the camera system.

A well engineered aluminum camera shell is not just a protective housing. It is a critical component that directly impacts performance, reliability, thermal stability, and installation precision of vehicle camera systems. Thoughtful design enables accurate imaging under real world automotive conditions, making aluminum a preferred material for modern ADAS and autonomous driving cameras.

Additional Options

If needed, this content can be converted into a longer industry article, integrated with a company introduction, or formatted for web or print.

Comparing Aluminum Camera Shells with Plastic and Magnesium Alternatives in Vehicle Camera Systems

The choice of material for vehicle camera shells directly influences durability, thermal stability, structural strength, and long term reliability. As the automotive industry advances toward higher precision sensing and ADAS applications, the requirements for camera shell performance continue to increase. Longto specializes in the technological development manufacture and processing of aluminum alloy products and provides stable high precision components for automotive markets.

Structural Strength and Rigidity

Aluminum delivers high rigidity that prevents deformation and maintains precise alignment of lens and sensor. Plastic has lower structural strength and is more prone to deformation under thermal stress which may cause calibration drift over time. Magnesium is stronger than plastic and lighter than aluminum but can be more brittle and often needs protective coatings to prevent corrosion.

Thermal Management Performance

Aluminum has excellent thermal conductivity which helps dissipate heat from sensors and improves long term imaging stability. Plastic has very low thermal conductivity and may accumulate heat in hot environments. Magnesium offers good thermal performance but is sensitive to oxidation and requires surface treatment.

Corrosion Resistance and Environmental Reliability

Aluminum works well with anodizing and powder coating to resist humidity road salt and chemicals which is ideal for long term outdoor automotive use. Plastic provides excellent corrosion resistance but may age under ultraviolet exposure. Magnesium is susceptible to corrosion without treatment and coating quality greatly affects durability.

Weight Considerations

Aluminum is lightweight while providing high durability which suits ADAS system designs requiring strong mounting. Plastic is the lightest option and is suitable for low load applications. Magnesium is slightly lighter than aluminum but has higher cost and processing challenges.

Manufacturability and Precision

With advanced CNC and extrusion equipment aluminum achieves high precision for mounting surfaces and internal cavities. Plastic injection molding supports large quantities but offers lower precision and may warp. Magnesium is more difficult to mold and machine and has a higher defect risk.

Cost Considerations

| Material | Material Cost | Manufacturing Cost | Long Term Maintenance | Notes |

|---|---|---|---|---|

| Aluminum | Medium | Medium | Low | Best performance balance |

| Plastic | Low | Low | Medium High | Heat deformation issues |

| Magnesium | High | High | Medium High | Requires protective coating |

Summary Comparison

| Performance Factor | Aluminum | Plastic | Magnesium |

|---|---|---|---|

| Structural Strength | High | Low | Medium |

| Thermal Conductivity | Excellent | Poor | Good |

| Corrosion Resistance | Excellent with anodizing | Good | Poor without coating |

| Weight | Medium | Very Light | Light |

| Manufacturability | Excellent | Good | Difficult |

| Cost Efficiency | High Value | Low Cost | High Cost |

| Suitable for ADAS | Yes | Limited | Conditional |

Aluminum camera shells offer the most balanced solution for vehicle camera systems by providing thermal stability structural strength corrosion resistance and manufacturing precision. These qualities are essential for ADAS and autonomous driving technologies. With proper surface finishing and precision machining aluminum is often the preferred choice over plastic and magnesium for high requirement automotive camera applications.

Additional Options

This content can be converted into a longer industry article integrated with a company introduction or optimized for web and print if needed.

English

English 日本語

日本語 Deutsch

Deutsch