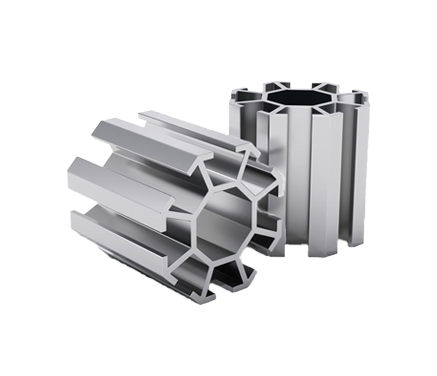

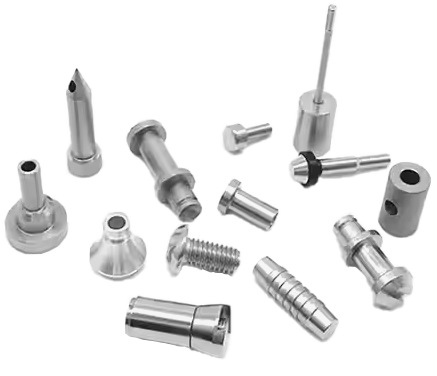

20 extrusion lines (600–6000T), 80+ CNC machines, 30 million parts annual output.

-

Full-Process Manufacturing

-

15+ Years of Engineering

-

ODM-Tier Cooperation

-

Global Export Presence

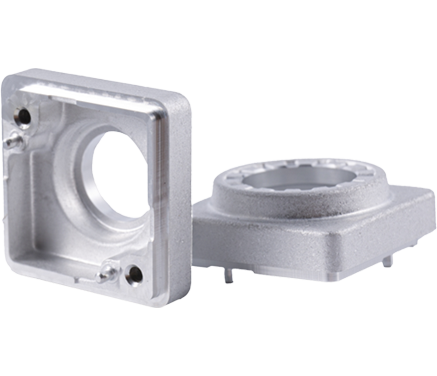

Product Categories

Explore our full range of aluminum parts for automotive, energy, aerospace, and industrial applications.

The pictures displayed are a general representation of form factor for the product line and may not accurately represent

this exact configuration in every detail due to custom builds and changes between similar products in our standard catalog.

Longto Precision Industry (Zhejiang) Co., Ltd.

-

Skilled Workers: 100+

Skilled Workers: 100+ -

Estimated Output Value: ¥300M+

Estimated Output Value: ¥300M+ -

Annual Capacity: 30 Million Units

Annual Capacity: 30 Million Units

our Clients

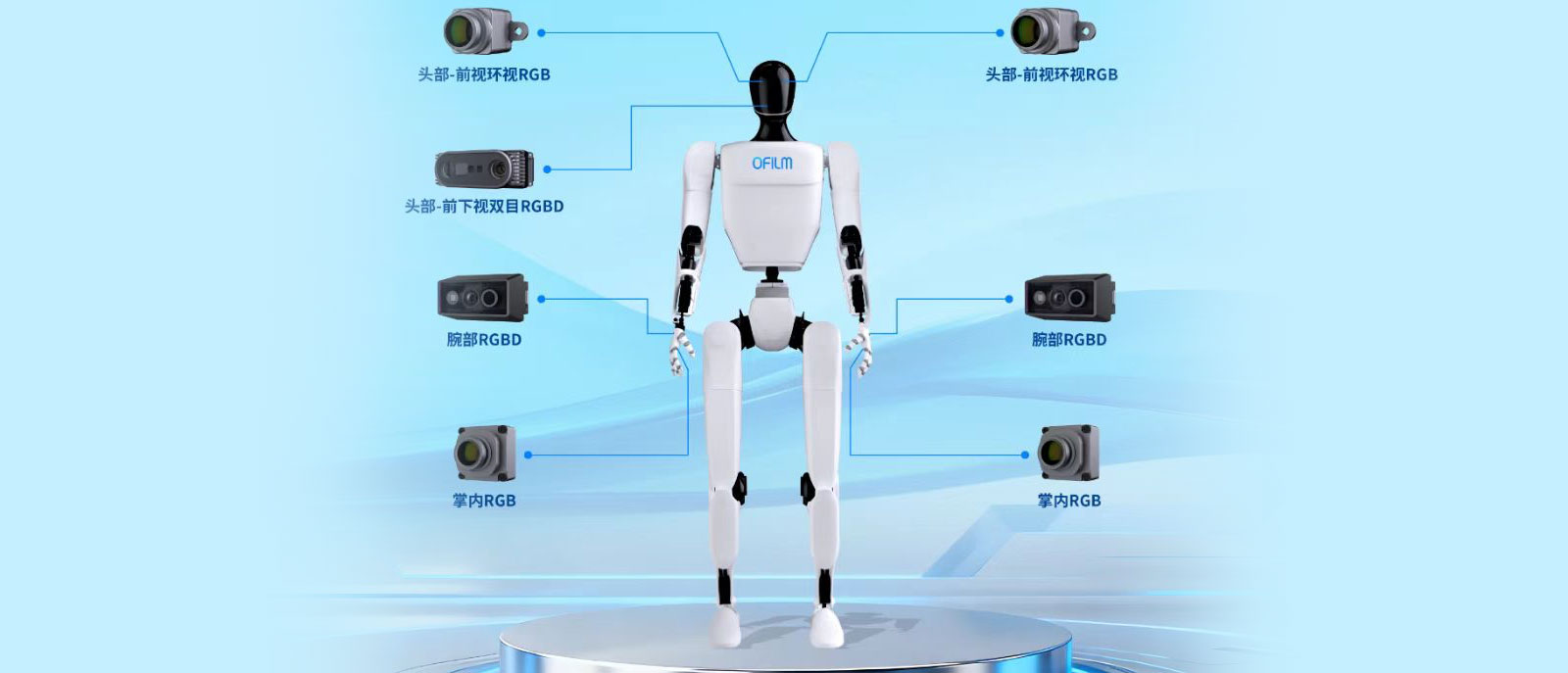

We are proud to serve global OEMs and leading companies with high-precision aluminum components, widely applied

in key

automotive models and ADAS systems. Their trust drives our commitment to excellence.

Our

Capabilities

-

-

IATF 16949 certified, equipped with CMMs and spectrometers for strict process control.

Quality Control

-

15+ years of cold extrusion R&D, with tooling co-development and rapid prototyping.

R&D Capability

Wide Applications Precise Solutions

We are proud to serve global OEMs and leading companies with high-precision aluminum components, widely applied

in key

automotive models and ADAS systems. Their trust drives our commitment to excellence.

English

English 日本語

日本語 Deutsch

Deutsch