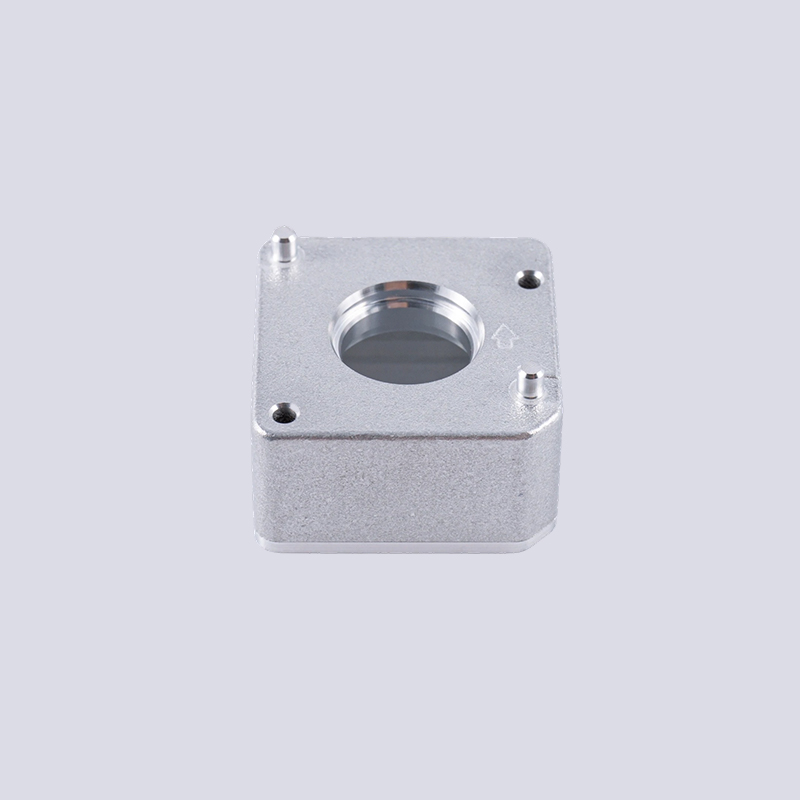

Aluminum Camera Shell Of Vehicle LT-20

The 2520138_A is a high-performance aluminum alloy housing designed specifically for advanced vehicle camera and sensor systems. Manufactured using the advanced one-shot cold extrusion process, this product perfectly integrates materials science, precision forming, and simulation technology. It is engineered to meet the stringent requirements of the smart driving sector for core components that are "lighter, stronger, more reliable, and more cost-effective."

About Us

Longto Precision Industry (Zhejiang) Co., Ltd.

Langto Precision is

China Aluminum Camera Shell Of Vehicle Manufacturers and Custom Aluminum Camera Shell Of Vehicle Suppliers, It focuses on the research and development and manufacturing of aluminum alloy products, equipped

with 20 extrusion lines and CNC processing centers, with complete integrated technology. Long-term service

for international customers such as Jaguar Land Rover, products are exported to the UK, Germany, Japan,

and the United States, and are widely used in automotive intelligent driving systems and high-precision

electronics.

-

Skilled Workers: 100+

Skilled Workers: 100+ -

Estimated Output Value: ¥300M+

Estimated Output Value: ¥300M+ -

Annual Capacity: 30 Million Units

Annual Capacity: 30 Million Units

News

All

Company News

Industry News

English

English 日本語

日本語 Deutsch

Deutsch