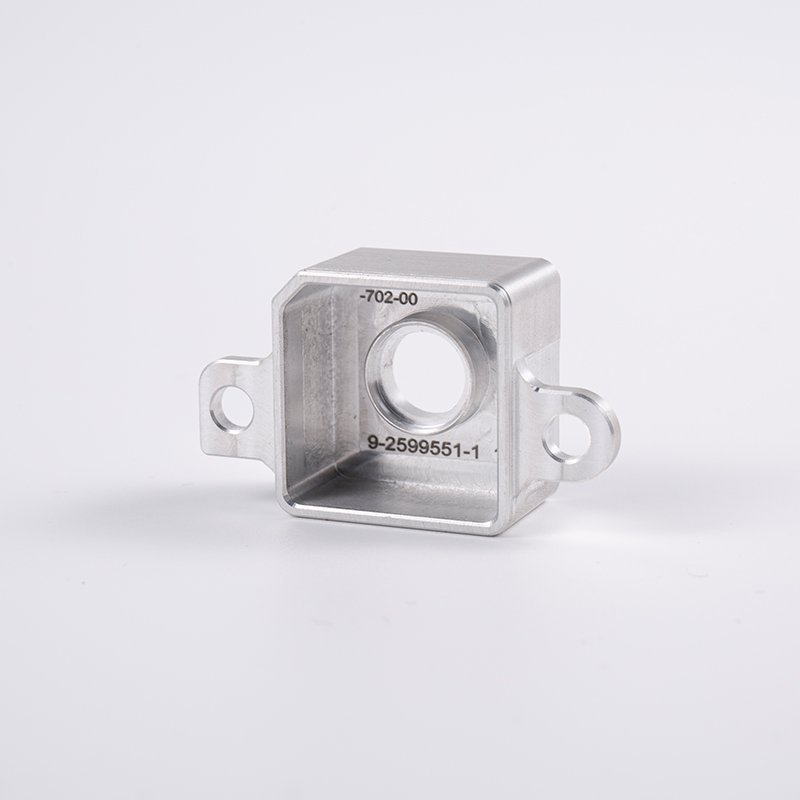

Aluminum Camera Shell Of Vehicle LT-18

As a partner of TE Connectivity, we are committed to delivering exceptional aluminum alloy housing solutions that meet the stringent requirements for high-precision, high-reliability components in the smart driving sector. Below is an introduction to our representative product series, developed based on core technologies and processes:

Core Product: High-Performance Vehicle Camera Housing

Example Product Model: 9-2599551-1_1_20250929

This product utilizes high-performance aluminum alloy materials (such as Al1070/AL1050) and is formed through advanced cold extrusion technology in a single process. It offers excellent heat dissipation and welding reliability, meeting diverse customer demands for material performance and environmental adaptability.

Longto Precision Industry (Zhejiang) Co., Ltd.

-

Skilled Workers: 100+

Skilled Workers: 100+ -

Estimated Output Value: ¥300M+

Estimated Output Value: ¥300M+ -

Annual Capacity: 30 Million Units

Annual Capacity: 30 Million Units

English

English 日本語

日本語 Deutsch

Deutsch