Aug 29, 2025

Aug 29, 2025

Posted by Administrator

Posted by Administrator

New Aluminum Alloy Surface Treatment Methods Emerge, with Significant Performance Improvement

With the continuous expansion of aluminum alloy applications in various fields, the requirements for its surface performance are increasingly higher. Recently, a series of new aluminum alloy surface treatment methods have been launched. For example, the adoption of advanced pulse anodizing technology can form a more uniform and dense oxide film on the aluminum alloy surface, significantly enhancing its corrosion resistance and wear resistance; there is also an innovative laser surface treatment process that can accurately change the micro-structure of the aluminum alloy surface, improving surface hardness while endowing the material with special optical or electrical properties. These new methods provide a more solid guarantee for the application of aluminum alloy products in harsh environments such as aerospace and marine engineering, and are expected to reshape the pattern of the aluminum alloy surface treatment market.

Recommended Products

-

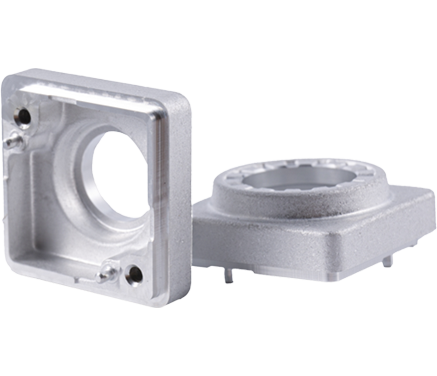

Aluminum Camera Shell Of Vehicle

Material: Al1070, reliable purity brings excellent heat dissipation of the product, which can ensure the reliability and stability of laser welding on the client side.

CNC: reliability of machining clamping;

Development: product tolerance and fit; structural design;

PPM: stability and consistency of product quality;

-

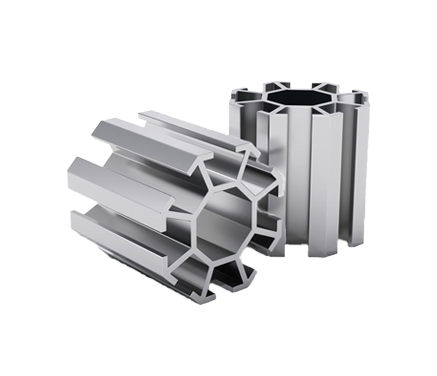

Aluminium Extrusion

Energy saving and environmental protection, high production efficiency, high product precision, and saving raw materials.

Process: 1, extrusion, 2, blanking, 3, grinding, 4, cold extrusion, 5, magnetic grinding, 6, CNC, 7, ultrasonic cleaning, 8, full inspection and packaging. -

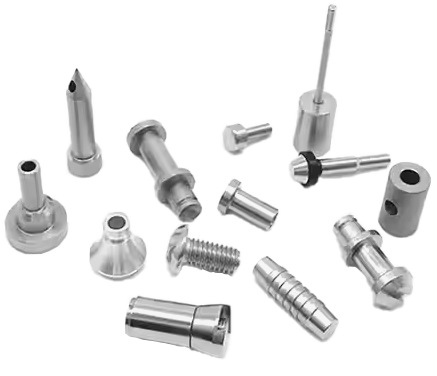

Aluminium Cold Forging Parts

The surface roughness of the product is low, and the strengthening effect of its deformation also improves the strength of the product.

English

English 日本語

日本語 Deutsch

Deutsch