Aug 29, 2025

Aug 29, 2025

Posted by Administrator

Posted by Administrator

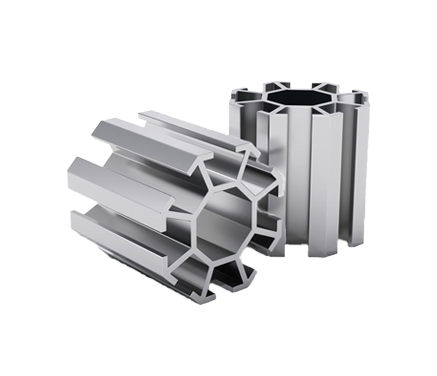

Innovation and Upgrade of Aluminum Alloy Extrusion Technology Drives Industry Capacity Expansion

Recently, a major breakthrough has been achieved in the aluminum alloy processing field. An enterprise has successfully developed a new type of extrusion process, which significantly improves the production efficiency and quality of aluminum alloy profiles by optimizing mold design and extrusion parameters. It is reported that the new process can realize the forming of more complex profile structures while reducing material waste. Industry experts stated that this innovation will promote the wider application of aluminum alloy products in construction, automotive, electronics, and other industries. It is expected that within the next two years, the overall industry capacity will increase by 15% - 20% due to similar technological innovations, strongly driving the aluminum alloy industry towards high-end development.

Recommended Products

-

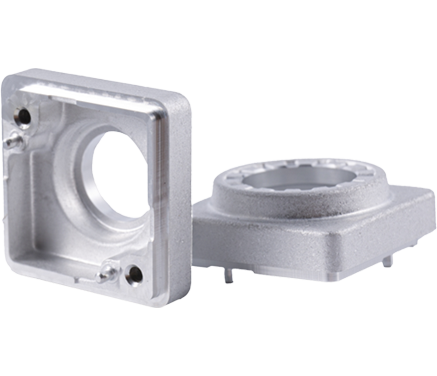

Aluminum Camera Shell Of Vehicle

Material: Al1070, reliable purity brings excellent heat dissipation of the product, which can ensure the reliability and stability of laser welding on the client side.

CNC: reliability of machining clamping;

Development: product tolerance and fit; structural design;

PPM: stability and consistency of product quality;

-

Aluminium Extrusion

Energy saving and environmental protection, high production efficiency, high product precision, and saving raw materials.

Process: 1, extrusion, 2, blanking, 3, grinding, 4, cold extrusion, 5, magnetic grinding, 6, CNC, 7, ultrasonic cleaning, 8, full inspection and packaging. -

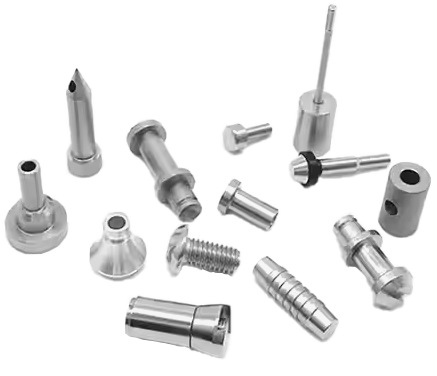

Aluminium Cold Forging Parts

The surface roughness of the product is low, and the strengthening effect of its deformation also improves the strength of the product.

English

English 日本語

日本語 Deutsch

Deutsch