Aug 29, 2025

Aug 29, 2025

Posted by Administrator

Posted by Administrator

Surging Demand for Aluminum Alloy Auto Parts in the Automotive Industry Drives Industrial Collaborative Development

Affected by the trend of automotive lightweight and the rapid rise of the new energy vehicle industry, aluminum alloy parts are being increasingly widely used in automobile manufacturing. In order to reduce vehicle weight and improve cruising range, automakers have seen explosive growth in demand for aluminum alloy parts such as anti-collision beams, body structural parts, and battery trays. This trend has prompted aluminum alloy manufacturers to strengthen in-depth cooperation with auto parts suppliers, forming a whole-industry-chain collaborative innovation model covering material R&D, product design, and large-scale production. It is expected that in the next few years, the market scale of aluminum alloy auto parts will grow at an annual rate of 20% - 25%, driving the accelerated upgrading of the entire aluminum alloy industry.

Recommended Products

-

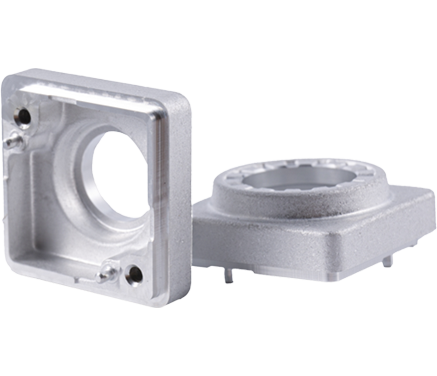

Aluminum Camera Shell Of Vehicle

Material: Al1070, reliable purity brings excellent heat dissipation of the product, which can ensure the reliability and stability of laser welding on the client side.

CNC: reliability of machining clamping;

Development: product tolerance and fit; structural design;

PPM: stability and consistency of product quality;

-

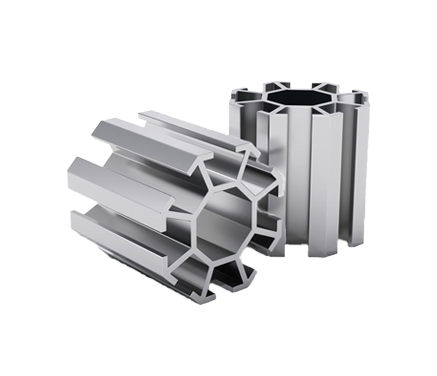

Aluminium Extrusion

Energy saving and environmental protection, high production efficiency, high product precision, and saving raw materials.

Process: 1, extrusion, 2, blanking, 3, grinding, 4, cold extrusion, 5, magnetic grinding, 6, CNC, 7, ultrasonic cleaning, 8, full inspection and packaging. -

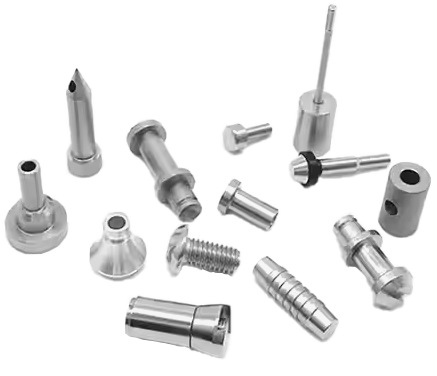

Aluminium Cold Forging Parts

The surface roughness of the product is low, and the strengthening effect of its deformation also improves the strength of the product.

English

English 日本語

日本語 Deutsch

Deutsch