Core Technical Advantages

1. Advanced Forming Technology

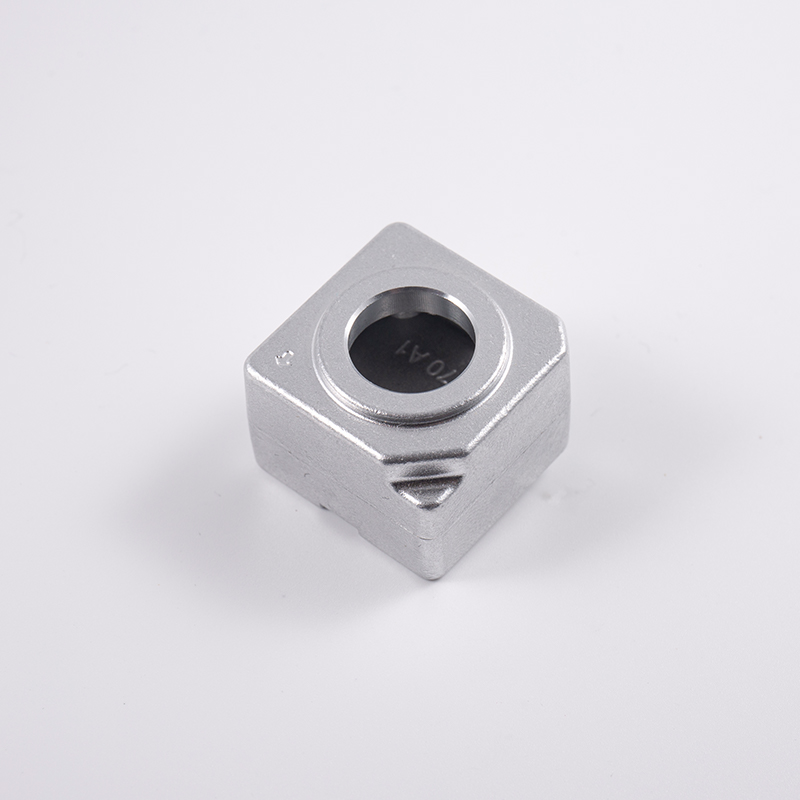

One-step Cold Extrusion Forming: Adopts a gradient pressure cold extrusion process combined with custom mold design to address uneven metal flow issues, achieving high-precision requirements with no draft angle on the housing.

Material and Structural Optimization: Adapts to low-yield-strength aluminum alloy materials, meeting thread structure strength requirements and enhancing overall reliability.

2. Precision Manufacturing Capability

Digital Twin Verification: Utilizes Deform simulation for forming analysis and 3D modeling design for dual verification, ensuring process feasibility.

CNC Precision Machining: Clamping accuracy reaches the micron level, ensuring clamping surface flatness precision ≤0.05mm.

Full In-house Production Process: From aluminum ingots to finished products, the entire process is completed within the factory, with full quality control throughout.

Product Performance Features

Structural Design

Integrated Structure: Eliminates welding weak points and sealing risks (expandable to integrated FAKRA rear housing design).

High Heat Dissipation: Aluminum alloy material combined with optimized structural design improves heat dissipation efficiency by 30% compared to traditional processes.

High Assembly Precision: Meets micron-level assembly requirements for vehicle cameras and lens modules.

Surface Treatment and Durability

Complete Surface Treatment System:

Ultrasonic Surface Cleaning: Removes microparticle contaminants.

Surface Passivation Treatment: Enhances corrosion resistance.

Surface Oxidation Treatment: Optional anodizing or micro-arc oxidation.

Stringent Environmental Validation:

Salt spray testing exceeds 96 hours (meets C5 corrosion environment standards).

High and low-temperature cycle testing (-40℃ to +125℃).

Vibration and mechanical shock testing.

Technical Patents and Industry Recognition

Patent Protection

Our company has applied for a Chinese patent for the cold extrusion process of vehicle camera housing (CN 120772428 A). This technology fills the process gap in the domestic field of metal plastic forming for core components of intelligent driving systems.

Industry Position

Leader in Cold Extrusion Camera Housing Technology: 15 years of aerospace-grade cold extrusion technology.

Production Capacity Plan: Production capacity will reach 30 million sets in the next three years, with output value exceeding RMB 300 million.

Industry Recognition: Selected as one of the Top Ten News of the China Forging & Stamping Association, and participates in industry standard discussions.

Application Customers and Partners

Existing Customers

International Brands: Jaguar Land Rover (UK), Sony, Panasonic, TE Connectivity, Rosenberger.

Automobile Manufacturers: Toyota, Nissan, Volkswagen, BMW, Audi, Tesla.

Domestic New Energy Brands: Xiaomi, Huawei, Li Auto, Chery, etc.

Partners

Shanghai Baolong Automotive Corporation: Long-term strategic partner, jointly developing core components for intelligent driving vision systems.

Domestic and International Tier-1 Suppliers: Provide bulk solutions for multiple well-known automotive supply chains.

Why Choose Langtu's Cold Extrusion Housing?

Higher Reliability: No weld seams or porosity defects, product consistency exceeds 99.8%.

Better Cost Efficiency: Reduces machining processes, and material utilization rate increases to over 85%.

Faster Delivery: Mold lifespan exceeds 500,000 cycles, supporting rapid mass production.

More Advanced Technology: Continuous R&D investment, process iteration leads the industry by 6-12 months.

Langtu Precision Industry is committed to becoming the industry standard-setter for cold extrusion camera housings. We will continue to provide the most reliable structural components for global intelligent driving systems with aerospace-grade technical standards. The 200000136871-JG-Front Housing is not just a product but a technological achievement developed in collaboration with Shanghai Baolong Automotive Corporation to advance the industry.

Skilled Workers: 100+

Skilled Workers: 100+  Estimated Output Value: ¥300M+

Estimated Output Value: ¥300M+  Annual Capacity: 30 Million Units

Annual Capacity: 30 Million Units

English

English 日本語

日本語 Deutsch

Deutsch