Security & Civil Electronics

-

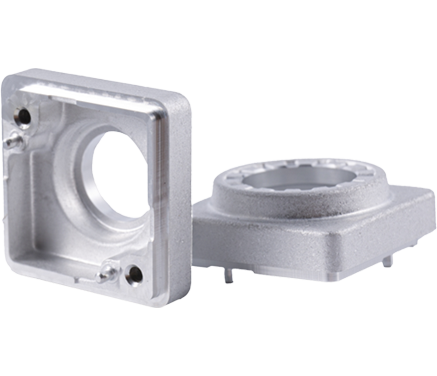

Aluminum Alloy Components Suppliers

Material: Al1070, reliable purity brings excellent heat dissipation of the product, which can ensure the reliability and stability of laser welding on the client side.

CNC: reliability of machining clamping;

Development: product tolerance and fit; structural design;

PPM: stability and consistency of product quality;

-

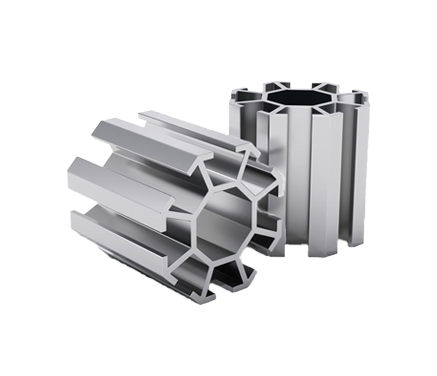

Aluminum Alloy Components Suppliers

Energy saving and environmental protection, high production efficiency, high product precision, and saving raw materials.

Process: 1, extrusion, 2, blanking, 3, grinding, 4, cold extrusion, 5, magnetic grinding, 6, CNC, 7, ultrasonic cleaning, 8, full inspection and packaging. -

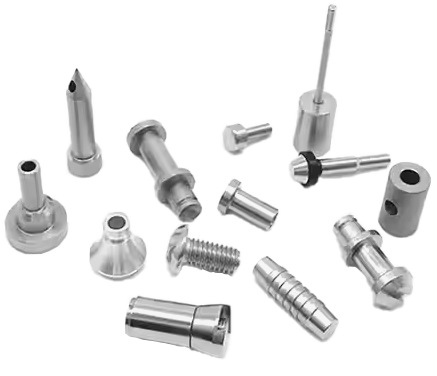

Aluminum Alloy Components Suppliers

The surface roughness of the product is low, and the strengthening effect of its deformation also improves the strength of the product.

Longto Precision Industry (Zhejiang) Co., Ltd.

-

Skilled Workers: 100+

Skilled Workers: 100+ -

Estimated Output Value: ¥300M+

Estimated Output Value: ¥300M+ -

Annual Capacity: 30 Million Units

Annual Capacity: 30 Million Units

News

How Aluminum Alloy Components Improve Structural Strength and Weight Reduction?

Aluminum alloy components play a key role in modern engineering due to their balance of mechanical strength, low weight, and good workability. Compared with traditional materials such as steel or pure aluminum, aluminum alloys deliver performance benefits across industries including automotive, aerospace, construction, electronics, and machinery.

High Strength to Weight Ratio

One major advantage of aluminum alloy components is their high strength to weight ratio. Aluminum alloys can reach tensile strengths similar to mild steel while weighing about one third as much. This enables engineers to design strong structures with much lower mass.

Benefits

Lower energy consumption in vehicles and aircraft. Easier handling and installation in construction and machinery. Reduced material usage without compromising safety.

Improved Structural Strength Through Alloying and Heat Treatment

Pure aluminum is relatively soft. When alloyed with elements such as magnesium, silicon, copper, zinc, or manganese, it achieves greater strength and durability.

How strength is improved

Solid solution strengthening where alloying elements dissolve into the aluminum matrix and increase hardness. Precipitation hardening achieved by heat treatments that form fine particles which block dislocation movement and raise strength. Grain refinement through controlled processing that improves toughness and fatigue resistance.

Result

Aluminum alloy components can withstand heavy loads, vibration, and cyclic stresses, making them suitable for aircraft frames, automotive suspension parts, and industrial machine components.

Lightweight Properties Enhance Efficiency and Performance

Low density of aluminum alloys reduces overall weight, which improves system efficiency.

In automobiles

Lower vehicle weight improves fuel economy, enhances acceleration and braking, and reduces emissions.

In aerospace

Weight savings reduce operating cost, allow higher payload capacity, and improve flight performance.

In industrial machinery

Lighter moving parts reduce inertia and improve response speed and overall efficiency.

Excellent Corrosion Resistance for Long Term Structural Integrity

Aluminum alloys form a natural protective oxide layer. With anodizing or surface coatings, corrosion resistance is further improved.

This prevents structural weakening from oxidation, reduces maintenance needs, and extends service life in harsh environments such as marine and outdoor applications.

Design Flexibility Enhances Structural Optimization

Aluminum alloys are highly formable and compatible with many manufacturing methods including extrusion, die casting, CNC machining, forging, and sheet forming. Engineers can design optimized geometries such as reinforced ribs and hollow profiles that improve strength to weight ratio.

Aluminum alloy components improve structural strength while enabling significant weight reduction by combining a high strength to weight ratio, advanced alloying and heat treatment methods, natural corrosion resistance, flexible manufacturability, and the ability to produce optimized lightweight designs. These advantages make aluminum alloys essential in industries that require performance, durability, and efficiency.

Comparing Aluminum Alloy Components with Steel and Composite Alternatives in Modern Engineering

In modern engineering, material selection determines the balance between structural strength, weight efficiency, durability, manufacturability and cost. Aluminum alloy components are versatile and often compete directly with steel and composite materials across automotive, aerospace, industrial and structural applications.

Aluminum Alloy versus Steel

Weight and Strength Efficiency

Steel offers very high tensile strength and durability but is significantly heavier. Aluminum alloys provide a superior strength to weight ratio, enabling lower component mass while maintaining mechanical performance.

Steel density is about 7.8 g per cm3. Aluminum alloy density is about 2.7 g per cm3. This difference makes aluminum alloys attractive where fuel efficiency, payload improvement or dynamic performance are critical.

Corrosion Resistance

Steel requires coatings or galvanizing to prevent rust. Aluminum forms a natural protective oxide layer and gains further durability with anodizing or powder coating. This makes aluminum more suitable for outdoor, marine and chemical exposure environments.

Manufacturability

Aluminum extrusion enables complex hollow or rib reinforced shapes that are costly or difficult with steel. This supports lightweighting and structural optimization.

Aluminum Alloy versus Composite Materials

Weight Comparison

Composites such as carbon fiber can be lighter and offer high stiffness, but they are more expensive and complex to produce. Aluminum alloys deliver a balanced combination of performance, cost and processability for many applications.

Impact and Fatigue Behavior

Composites may exhibit brittle failure modes, while aluminum alloys provide more predictable deformation and energy absorption. For high impact applications such as automotive crash structures, aluminum often offers safer and more reliable performance.

Thermal and Electrical Conductivity

Composites have limited thermal and electrical conductivity, which restricts their use in heat dissipation and electromagnetic shielding. Aluminum alloys excel in heat transfer and conductivity, making them suitable for battery trays, electronic enclosures and heat exchangers.

How Longto Strengthens the Competitiveness of Aluminum Alloy Solutions

Longto enhances aluminum alloy advantages through integrated extrusion, surface treatment and precision machining capabilities, enabling structurally optimized, lightweight and durable components for demanding industries.

Production Capabilities

| Capability Category | Description |

|---|---|

| Extrusion Capacity | 20 extrusion lines with tonnages from 600 to 6000 |

| Surface Treatment | 2 anodizing lines and 3 powder coating lines |

| Precision Machining | CNC, milling machines, lathes, drilling machines and punching machines |

| Supply Chain Advantage | Long term partners for plastic and stainless steel accessories |

| Automotive Cooperation | Direct export to the UK for Jaguar XE, XF, F PACE and I PACE |

| New Development | Cold extrusion parts now supplied to UK and US markets |

Application Case in Automotive Industry

The automotive sector increasingly replaces steel with aluminum to improve energy efficiency and meet emissions regulations. With precision machining and surface treatment, aluminum parts can meet strict OEM standards.

Typical benefits include up to 40 percent weight reduction compared to steel components, improved corrosion resistance, enhanced structural stiffness through optimized extrusion profiles and compatibility with CNC and multi stage machining for high accuracy.

Aluminum alloy components deliver a balanced combination of light weight, mechanical performance, corrosion resistance and manufacturability. When supported by extensive extrusion, machining and surface treatment capabilities, they are a strong alternative to steel and composites for industries that require performance, efficiency and structural optimization.

English

English 日本語

日本語 Deutsch

Deutsch