Production Lines

& Workflow

We operate a full-chain manufacturing process covering aluminum extrusion, precision machining, and surface finishing, ensuring seamless integration from raw material to final product.

-

Raw Material Extrusion

1

-

Cutting

2

-

Forging Blank Grinding

3

-

Coating

4

-

Cold Extrusion

5

-

Forgings Grinding

6

-

CNC

7

-

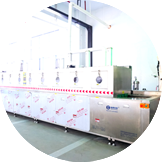

Ultrasonic Cleaning

8

-

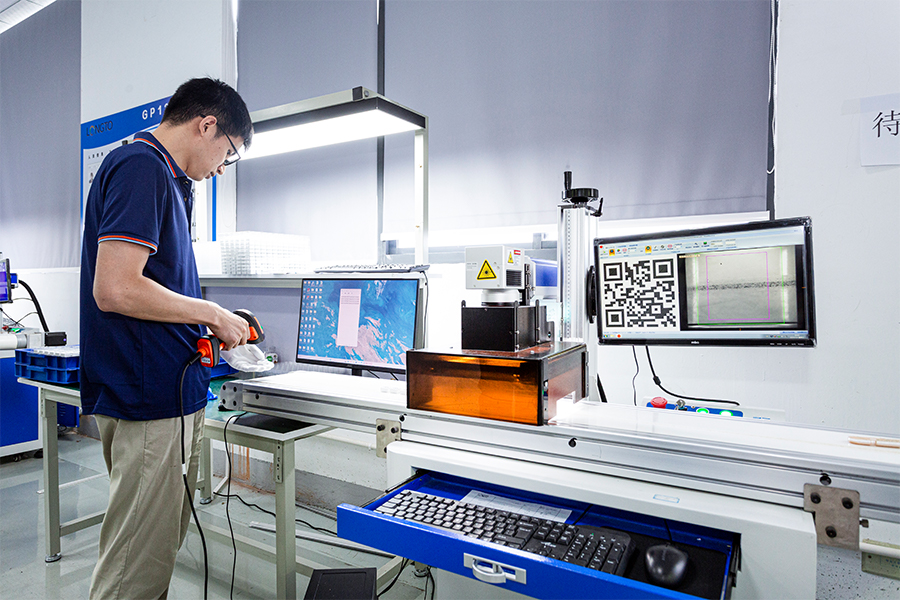

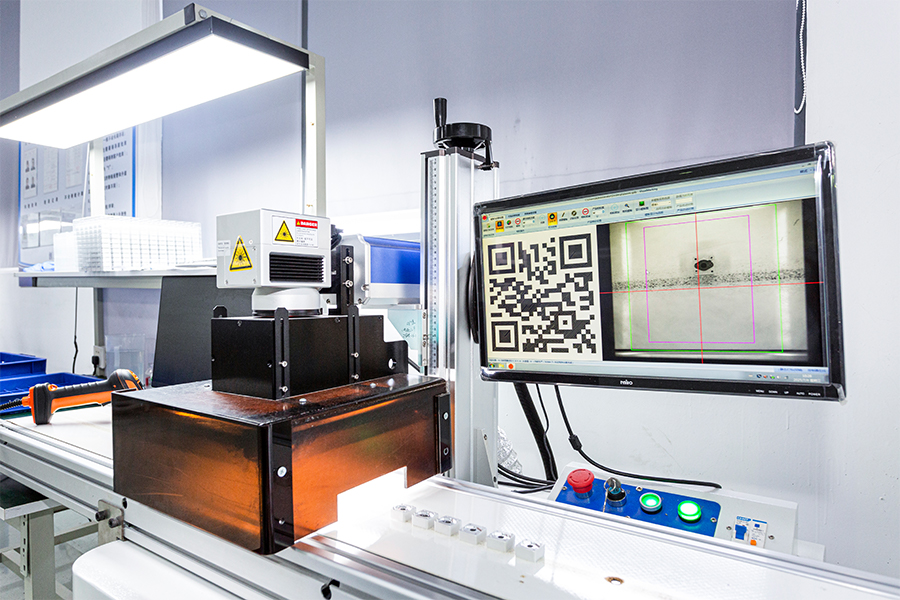

Laser Engraving

9

-

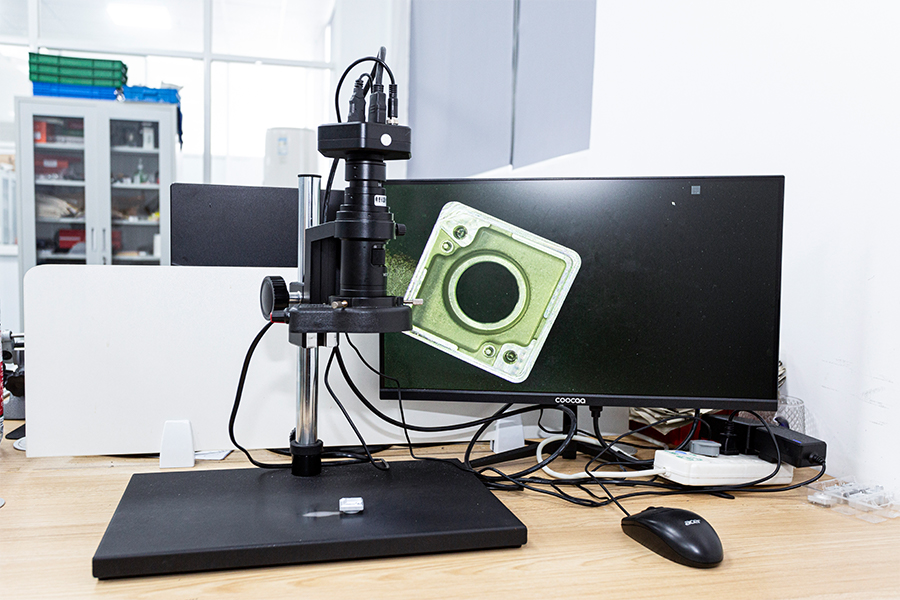

Full Inspection

10

-

Packaging

11

-

Shipment

12

Production Capacity

& Delivery Performance

With a modern production facility and skilled team, we deliver flexible manufacturing solutions that

efficiently handle everything from prototyping to mass production — ensuring quality and on-time

delivery.

-

6,000 M²

Facility Area

-

30 Million Units

Annual Output

-

RMB 300 Million +

Annual Output Value

-

30–60 Days²

Delivery Time

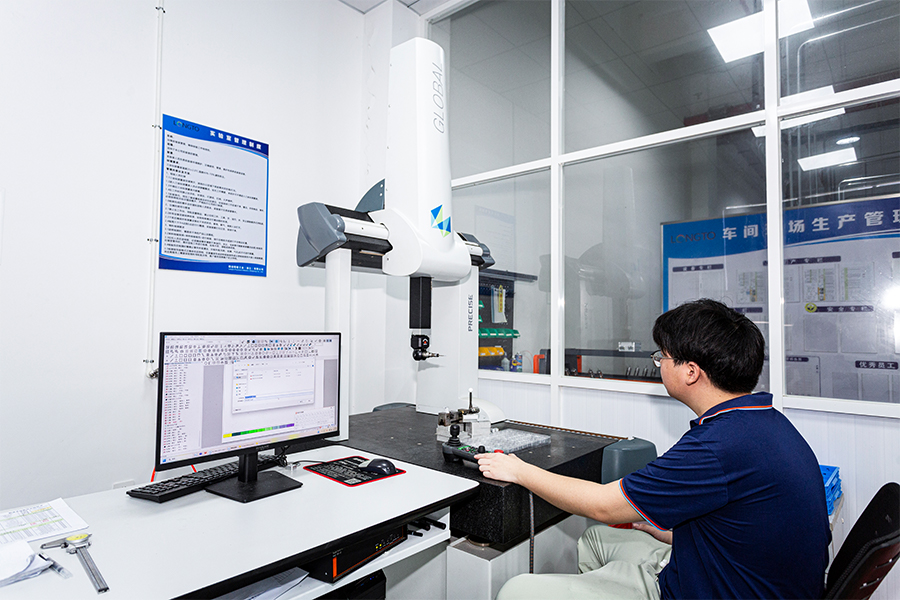

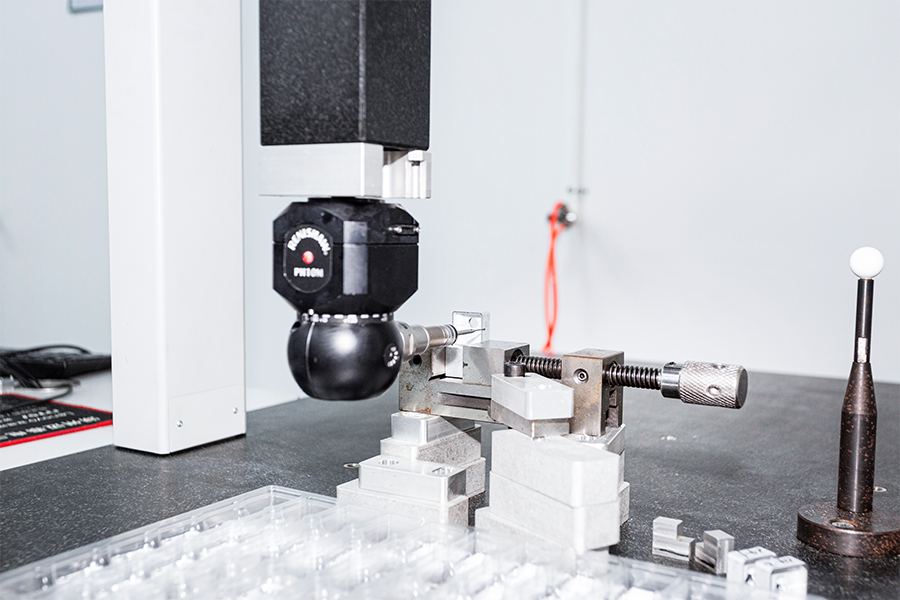

Key Equipments

Our facility is equipped with over 30 high-precision CNC machining centers, 20 aluminum extrusion lines (ranging from 600 to 6000 tons), 2 anodizing lines, 3 powder coating lines, and a full set of supporting equipment including stamping, milling, and drilling machines. This comprehensive production system enhances efficiency and ensures precision and consistency in both small and large-scale aluminum component manufacturing.

English

English 日本語

日本語 Deutsch

Deutsch